Characterizing bamboo aggregate foamed concrete for sustainable construction: thermal, acoustic, mechanical, and environmental aspects

Abstract

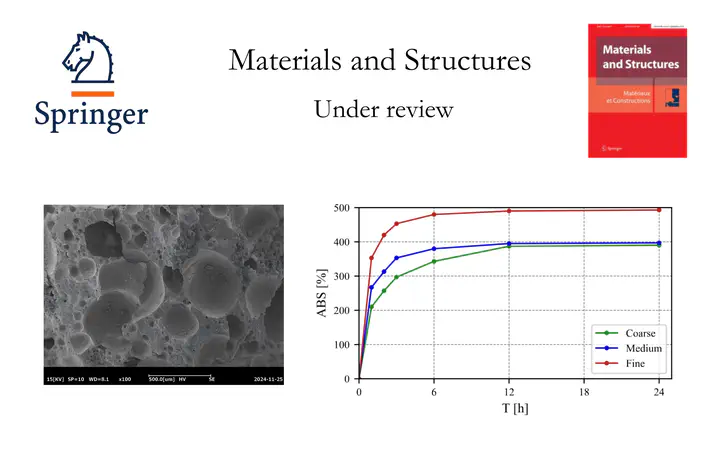

This study investigates bamboo-based foamed concrete as an eco-friendly alternative to conventional foamed concrete, aiming to evaluate its feasibility and performance. The primary objectives were to determine how the partial replacement of sand with bamboo aggregates at various substitution ratios (1.25.%, 2.5%, and 5%) and particle sizes (fine, medium, and coarse) affects thermal insulation, acoustic performance, and mechanical strength. Bamboo aggregates were produced from recycled residuals obtained during engineered bamboo panel manufacturing, promoting sustainability and waste reduction. Ten concrete mixes were tested, incorporating different proportions and sizes of bamboo aggregates. Comprehensive experiments included assessments of density, water absorption, microstructure analysis (SEM), thermal conductivity, sound insulation and absorption, compressive strength, and flexural behavior. The environmental impact was evaluated through a comparative carbon footprint analysis. Bamboo-based foamed concrete exhibited densities between 1003 and 1351 kg/m3, compressive strengths up to 11.45 MPa, and flexural strengths up to 2.61 MPa, suitable for non-load-bearing and moderate structural applications. Thermal conductivity ranged from 0.165 and 0.212 W/m· K, demonstrating superior insulation properties compared to traditional foamed concrete. Acoustic performance improved notably with Noise Reduction Coefficient (NRC) values reaching 0.31, although Sound Transmission Loss (ST L) was modest. Bamboo-based foamed concrete provides a promising sustainable alternative construction material, effectively balancing lightweight characteristics, satisfactory mechanical performance, improved thermal insulation, and enhanced acoustic properties. Further optimization is suggested to improve acoustic insulation performance for broader practical applications.

Highlights

-

Uses SLM to fabricate 316L stainless steel metamaterials.

-

Impact of smaller tendons and larger stu!ers in arrowhead structures.

-

Quasi-static and dynamic compressive behavior.

-

FEM and experiments validate auxetic behaviors.

-

Novel designs optimize protective performance

Publication process:

- Mar 2025 - Under review