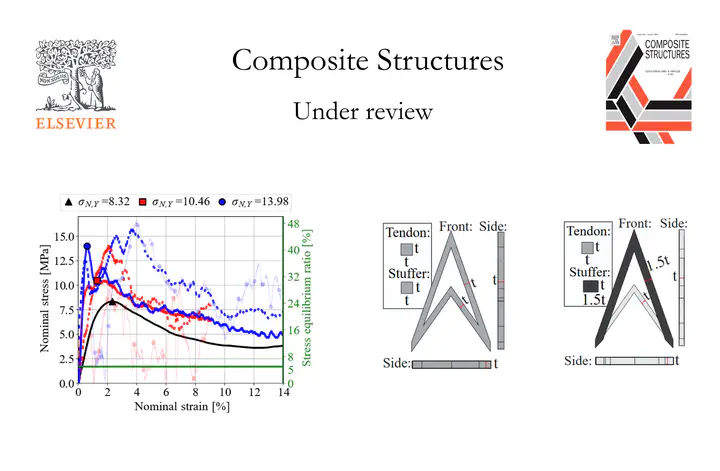

Enhanced Compressive Performance and Energy Absorption in SLM-Fabricated 316L Arrowhead Auxetics via Tendon and Stuffer Geometry Modification

Abstract

This study investigates how geometric modifications in double-arrowhead auxetic lattice structures affect compressive behavior and energy absorption. Lattices were fabricated in 316L stainless steel using Selective Laser Melting (SLM) at relative densities of 5%, 10%, and 15%. We compared a baseline design (Lat1N, equal-sized tendons and stuffers) with a modified design (Lat1S, smaller tendons and larger stuffers). Mechanical performance was assessed via quasi-static and dynamic (SHPB) compression tests, supported by FEM simulations. Results show that increasing density improves mechanical properties in both designs. Lat1S consistently outperformed Lat1N: at 15% density, Lat1S showed 21% higher quasi-static plateau stress (42MPa vs. 35MPa) and 24% higher dynamic stress under 0.25MPa impact (48MPa vs. 38.5MPa). Yield stresses also increased accordingly. Energy absorption per volume reached 10.67MJ/m³, and specific energy absorption (SEA) peaked at 32J/g—around 20% higher than Lat1N. Both designs exhibited strain rate sensitivity, with DIF values from 1.15 to 1.85. The improved performance of Lat1S is attributed to enhanced load distribution via larger stuffers, suggesting a viable design strategy for auxetic metamaterials in impact-resistant applications.

Highlights

-

Uses SLM to fabricate 316L stainless steel metamaterials.

-

Impact of smaller tendons and larger stu!ers in arrowhead structures.

-

Quasi-static and dynamic compressive behavior.

-

FEM and experiments validate auxetic behaviors.

-

Novel designs optimize protective performance

Publication process:

- Apr 2025 Under review